Saving the world from Solid State

Warning for Fake Mesh Tubes

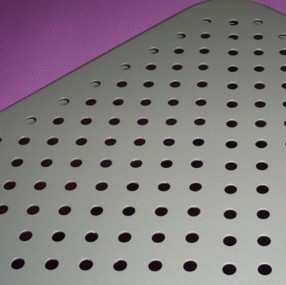

In Germany, we have an saying: Copying of your products is the highest form of recognition. Only, when I see what the Chinese factories are doing, they use punched Anode anodes, and call that mesh. For buyers which want the optical illusion only, it's probably ok, but in case you wanted to buy mesh tubes, and get send punched Anode anodes, there is something wrong. So we speak out a warning here for this.

What is mesh?

The word mesh is by definition for things that are woven into each other. With mesh wire, this is what you get with an Emission Labs ®mesh tube. The Chinese are selling so called 'mesh tubes', which are Solid Plate tubes, with very fine holes in the anode.

The special sound of mesh tubesThis can not be achieved by light effect. It can only be reached by low resonance and other mechanical properties of the wire mesh, such as the irregular surface. Also there is an electrical (and so sound) effect of very small fraction of the electrons initially escaping thought the holes. This electrical current is not lost, as the electrons are reflected by the glass, back to the anode. The Blue light effect of mesh tubes.This blue effect is mostly known from tubes like EL34, which have relatively large the adjustment holes at the sides of the anode. Through these holes, a certain amount of electrons will escape, building the blue patterns on glass or the mica. The EML Mesh tubes will show a similar blue haze, right opposite to the anode of the 300B mesh. Even so, it may show a shadow pattern of the anode and the middle cooler. After some use, the fluorescent effect of the glass will disappear partially. This is normal, and no sign for anything. We just want to point out here the light effect and how it will develop. Please regard it as something interesting, related to mesh tubes, but the light effect is not a product specification, and it is bit different for all tubes. |

Mesh wire, used in other applications:Mesh wire is used in industry as damper element, but I never heard of punched Anode material being used for t his as such. Here is an examples of damper element with mesh. |

|

Some sellers try to blow some smoke around it, and call it semi mesh, which word suggests something comparable, but also this is not so. The only thing which is the same as real mesh, is the light effect. For the rest, it is a Solid Plate tube, with holes in it. So using honest language I call them fake mesh, so there is no misunderstanding. A product is made of mesh, or it is not. Same as there is no such thing as a little bit pregnant.

Some sellers try to blow some smoke around it, and call it semi mesh, which word suggests something comparable, but also this is not so. The only thing which is the same as real mesh, is the light effect. For the rest, it is a Solid Plate tube, with holes in it. So using honest language I call them fake mesh, so there is no misunderstanding. A product is made of mesh, or it is not. Same as there is no such thing as a little bit pregnant.

Punched Anode tubes.

Punched Anode tubes.