Technical Bulletin TB-05

Best Tube Life, related to Heater Voltage

written by Jac van de Walle

We see often, there is great misunderstanding about how to give good meaning to data in the data sheets. The data sheet is the only source of information, directly written for the user. The idea of a data sheet is not to publish some limits, which as long as you don't exceed them, will assure you best performance and longest life time. Unfortunately, it is not that easy.

To achieve best tube life, the cathode has to be kept in good condition. This requires for the cathode itself, having the ideal temperature, and a minimum anode current. Damaging factors for the cathode can be too high or too low steady state current, too high peak current, too fast or too slow start up, and too low or too high temperature of the whole tube.

It can be quickly seen from all commercial data sheets, the manufacturer reserves great freedom for himself, or not even specify some parameters at all. Though these exist, and though these are important. At the same time, you will also see, there is no data sheet without clearly specified heater voltage tolerance. Also this tolerance is quite narrow. It is most of the time 4...5% only. In a data sheet, which is full of average parameters, any clear limit must be seen as something important. Unfortunately, reality is another. When we see a problem with an amplifier, first thing we ask for, is a measurement of the heater voltage. Most of the time it appears then, the user does not know, and is not helpful to find it out. Reason for this can be there is no service point near by, or the whole amplifier is too bulky. Still that doesn't change, such malfunctioning problems which develop slowly, are often a heater voltage error.

This technical bulletin is only about the influence of the heater voltage on tube lifetime.

In short we can say this:

- The MAXIMUM lifetime will be achieved at a heater voltage of ZERO percent deviation.

- The MINIMUM lifetime is achieved at maximum allowed tolerance, in either direction.

- When going below rated heater voltage, problems come quickly, yet effect of over heating is more permanent

Lifetime vs heater voltage

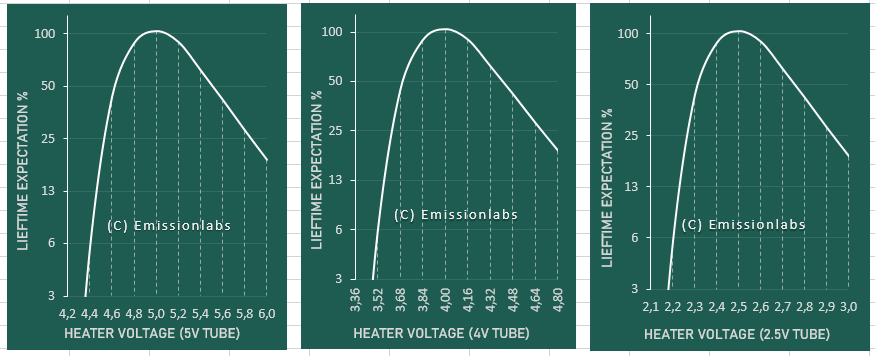

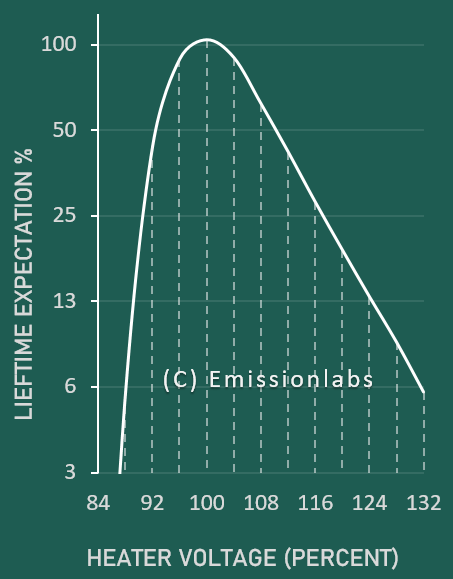

A similar curve was first presented by Howard Tremaine in 1959, in his "Audio Encyclopedia", which you can read here for free for one hour, after registration. This is a very good way to show the exponential effect of heater voltage on tube life. The military handbook describes the exponential relation between heater voltage and lifetime as well. We can only agree with it. The values we present here, are a fair estimation of our own tube data. As you can see, the slope on the left side is much steeper. Indicating, this is a larger cause of malfunctioning.

The effect of under heating can be drastic. Best life time is achieved at the specified heater voltage only, without deviation. For High Current / Low voltage tubes, such as the 2A3, an additional issue comes to it. This has nothing to do with EML, all 2A3 tubes are subject to this: The voltage drop across the tube sockets can have an influence. That is because 2.5 Ampere is a lot, and the resistance path is present at both pins, so we have it twice. Then, having 0.1V drop perhaps, may seem neglectable, but it is not! This will have a larger effect on a 2.5V tube, than it has on a 5V tube. Moreover 5V tubes draw half the current only. Click on the image below, for a magnified view. Suppose here, you heat a 2A3 with 2.4V only, which would be "just ok". Now, move to 2.3V and as you see, lifetime is reduced to 40% only. Such a big difference! Doing the same with 300B, there is almost no such issue. Voltage drop at the same contact quality, is only half, because filament current is lower. And then, check at the 5V Curve, half of 0.1V (so 50mV) has just a small effect. So going from 4.8 to 4.75, still stays somewhere in the "top" of the curve. Though you will agree, exactly 5V is much better.

Similar curves, by heater voltage:

Background information, you may find interesting.

Too high and too low heater voltage, each at it's own way, will impair lifetime of the tube. The cathode coating is mainly Barium Oxide, but to make the tube work, a thin layer of Metallic Barium is formed by a process called Electrolysis. The current for the electrolysis is the plate current itself.

Higher than normal filament temperature will evaporate the metallic Barium layer, which process accelerates with higher temperature. Whereas the Electrolysis is a constant factor, depending on the DC current of the tube. So it is clear, that above a certain temperature, there will be imbalance, the tube slowly looses it's metallic Barium layer, and emission becomes permanently reduced.

Lower than normal filament temperature starts another failure mechanism. This reduces the evaporation of metallic Barium which is good, but a certain evaporation still takes place. The forming of new metallic Barium however needs a minimum temperature, below which nothing is formed any more. This can be very confusing for silly experiments with reduced heater voltage. Initially, it seems the tube works fine at lowered heater voltage. The experimenter thinks he invented something, which idea nobody had before. Only after some 200...1000 hours, still no new metallic Barium is formed, while evaporation process did not stop. This begins to create dead spots in the cathode, which have no metallic Barium surface. Even so, the places which do have metallic Barium left, will be drawing all plate current, and wear faster. So after a period of good functioning, plate current begins to reduce, and then fully collapse.

This process however can be reversed, when the tube has not too many use hours. In that case, there is still enough Barium Oxide coating left, which will soon form metallic Barium again, when the filament temperature is increased to normal, and Electrolysis will begin to repair the tube.

Is DC heating better than AC heating?

Well yes and no. A disadvantage of DC heating is, users are advised by module sellers, to use a very un-ideal bias scheme. They get advised the connect the filament grounded with one end, which is easier from the view of the module. However this eliminates the property of the filament to reject any common mode signals. Such signals have a sound we all know. It is best described as 'hummmm'. Now, module builders say, their modules have no hum anyway. Still, what remains, the tube is no longer in auto bias mode. These "small" disadvantages are told to be worth it, since they claim current source heating is improving sound so much, that overall we have an large advantage. It's what they say, but this is plain marketing BS. Read also TB03 on this subject. They do not mention to, that a tube in Adjustable Bias Mode must be reduced 20% in dissipation, to prevent thermal runaway, which damages the tube completely.

We can only advise: Stay with Auto Bias, and symmetrical heating. To achieve symmetrical heating, just construct a classical auto bias, AC heated tube stage, and then simply connect DC to where you would have otherwise connected the AC voltage.

Electronic modules, once more.

Some are good, some are bad.

BAD: Slow heat up with electronics modules have the theoretical benefit, to prevent filament breakage with Tungsten tubes. This may seem good, but at EML we make only Barium tubes. So this benefit doesn't count for us. However, the tube stays much too long in a half-warm condition. What does this mean? For Tungsten tubes it is unimportant. Not so for Barium tubes, because these become their wear out mainly during the warm up moment, which lasts some 10 seconds. This wear out, is roughly the same as the rest of the hearing session. This is why users who have few, long hearing sessions, get a lot more use hours from their tubes, as those who have many short hearing sessions. Probably you already expected this outcome, but you need to see now why this is so. On purpose, some slow start modules stretch out the warm up period so several minutes. This has a devastating effect on the tubes! This should be avoided at any time.

GOOD: The benefit of (no slow start) regulated electronics is of course the filament voltage being exactly right. This is the easiest to fulfil and the most effective of all, when it comes to good tube lifetime.

With electronic modules, it looks to me, any kind of strange concept is adopted gratefully and uncritical, as long as it looks interesting, and when the maker say's it is something "new". Myself I write big question marks behind something new, because tube history is now 110 years old, and if something was so much better, it would have been done 100 years ago already.

Historical reality says: 4...5%.

Throughout history of making Barium coated electron tubes, we see always the same specifications for the heater voltage: +/- 4...5%. In some rare cases tubes are specified at +/-10%, but this does not mean these manufacturers have invented something which nobody else knew how to do it. This was only for special applications where it had to be specified this way, and a compromise was made with other factors. Also the opposite we see with some military tubes. They are specified for not many hours, but during that time, the tube can take a lot of stress.

Mechanisms

Tubes have a balance inside, to maintain and regenerate emission.

- The emissive Barium surface layer evaporates simply by heat of the filament. Also it can get hot by gas ions. Some protection comes from the electron cloud, which reduces the speed of the ions, but this protection is only partially, and is less effective at higher plate voltage, when the ions pick up more speed. This Barium layer is just a few microns thin, and evaporation accelerates very much at higher temperature. So just 5% more filament voltage has a much larger effect as just this 5%. Deeper inside the filament coating is the Barium Oxide depot. This migrates slowly to the surface, and forms new metallic Barium, closing the holes in the emissive layer.

- If the tube filament is not warm enough, there is not enough migration of new Barium to the surface. Of course there is also less evaporation, but the balance will fall into the direction of not enough migration. So the metallic Barium layer will slowly disappear. However now the depot is not used up. So such tubes may be recovered by just normal use.

- If the tube filament is really much too cold, it may begin to suffer from cathode poisoning, when gas residue reacts with the metallic Barium. This can develop into an emission killing surface. Such a tube may be recovered by the classical process, of over heating the filament. However care should be taken, not do this when it is not needed. In that case it doesn't help, and makes things only worse.

- The ideal situation comes, during normal use, when evaporation and regeneration are nicely in balance. as it should be. You can trust, we designed the filaments exactly in such a way, that this happens at exactly at....the specified heater voltage. (meaning +/- 0%).

Highest possible lifetime

Admitted, there are cases where lifetime is not the first concern, for instance when companies specify an amplifier with exceptional wide range of mains voltage, and still use AC heating for the tubes. Any change in the mains voltage will also mean a change in the heater voltage. In such cases it will come down to stressing the 5% limit. Or worse, they do not respect that this 5%, and we have a debate why they can not exceed this by just a few % extra. However when tube life is your first concern, deviation of the heater voltage should be 0%.

Conclusion

So after reading this, one may think, are EML tubes so sensitive against heater voltage deviation? The answer is: No, they are not more sensitive than other tubes. It is just every time when we get reported very high lifetime of our tubes, we find this was a result of good amplifier design and correct heater voltage. It must be said like this: At maximum deviation of the heater voltage, and no better than that, it should not come as a surprise to you, that lifetime will be also just within the specs as well. And no better than that. In other words: The less deviation of heater voltage, the longer the tubes will last, and this is so for any DHT, any brand, new made, or NOS.